Search Results

Filter Your Search

Category Group

Category Group

Shop by Category

O-rings as elastic loops that seal static and dynamic applications. They are used to seal the space between cylinders, pistons, pipes and tubes and can be made from various materials.

70 Durometer | Buna-N Rubber Material | 6 1/4 in Nominal Inner Diameter | 1/8 in Cross Section | O-Ring

Features

- Pressure range varies according to diametral clearance

- Temperature range of -40 °F to -240 °F

O-ring

90 Durometer | Buna-N Rubber Material | 0.468 in Nominal Inner Diameter | 0.078 in Cross Section | O-Ring Boss Gasket

Wear rings provide a hard-wearing surface that protects the cylinder walls and the piston rod from scoring and abrasion. By maintaining alignment and reducing side loads, these rings facilitate smoother piston movement and lower friction levels.

Nylon Material | 3 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Wear Ring

Features

- Scarf Cut wear ring

- Protection Against Wear

- Reduced Friction

- Extended Cylinder Life

- Operational Efficiency

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 6 1/2 in Nominal Inner Diameter | 1/4 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

Solid Urethane backup ring with a flat cross-section.

95A Durometer | Urethane Material | 3 1/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation

Solid Urethane backup ring with a flat cross-section.

95A Durometer | Urethane Material | 3 5/8 in Nominal Inner Diameter | 3/16 in Cross Section | Backup Ring

Features

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation

The PS1400 seals offer low friction and high strength in a compact double-acting piston seal design. The PTFE seal ring, combined with a rubber energizer, assures positive contact with the dynamic surface. The PS1400 is designed to fit ANSI/B93.32-1973 groove standards. Piston diameter “I” dimensions are given for pistons without wear rings.

15% Glass Filled PTFE Material | 2.608 in Nominal Inner Diameter | Piston Seal

Features

- Easy assembly

- Low friction capabilities

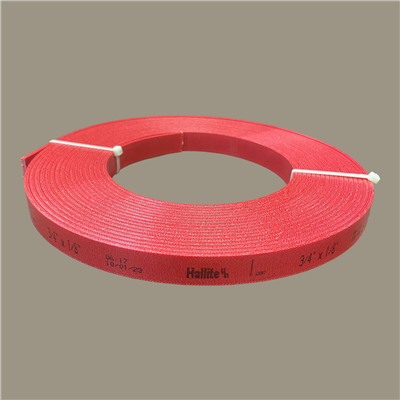

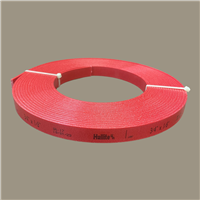

The Hallite 533 is capable of withstanding high side loads and preventing metal-to-metal contact between the piston and the bore or the rod and the gland.

The PA 533 material is heat stabilised 33% glass reinforced nylon 66, which offers excellent bearing properties.

Compatible with hydraulic and lubricating oils. The PA 533 material is not recommended for use in water based fluids (HFA) or where significant water is present, due to the swell of the nylon.