Search Results

Filter Your Search

Category Group

Category Group

Shop by Category

Style 850 u-seals offer excellent resistance to extrusion and abrasion. The round cross-section expander offers energized sealing from zero to 5,000 psi.

95A Durometer | Urethane Material | 1 3/8 in Nominal Inner Diameter | 3/16 in Cross Section | U-Seal

HT-4625X4000 has a wall thickness of 0.3125 in. The ID is 4 in and the OD is 4.625 in. The material is DOM 1026 Steel – ST52.3 and has been stress-relieved and annealed.

Full mill lengths will be cut to lengths between 12 ft and 19 ft long. Packages longer than 44 inches may have additional freight charges.

| 1-14 | $8.59 |

| 15-59 | $7.38 |

| 60-104 | $6.45 |

| 105-149 | $5.73 |

| 150+ | $5.16 |

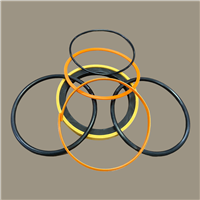

O-rings as elastic loops that seal static and dynamic applications. They are used to seal the space between cylinders, pistons, pipes and tubes and can be made from various materials.

70 Durometer | Buna-N Rubber Material | 1 7/8 in Nominal Inner Diameter | 1/16 in Cross Section | O-Ring

Features

- Pressure range varies according to diametral clearance

- Temperature range of -40 °F to -240 °F

AN wipers are ideal for light duty and pneumatic applications. Its main purpose is to prevent dirt and contaminants from entering the hydraulic or pneumatic systems. Suffix “SH” designates slotted heel design, “V” designates fluorocarbon material, and “B” designates carboxilated nitrile material.

90A Durometer | Urethane Material | 6 in Nominal Inner Diameter

Features

- Flexible, snap-in design for easy installation into closed housings

- Low compression set

CPO-1062 has a 1.062 in diameter with Standard Chrome. The base material is 1045 Carbon Steel with a yield strength of 75,000 psi.

ASTM A108 is the most commonly used and economical grade of shafting for hydraulic cylinder components, blower shafts, and mandrels.

- Extremely smooth surface finish

- Excellent wear and corrosion resistance

- Good strength and impact properties

- Good machinability

- Reasonable weldability

- Fair response to normal heat treating and induction hardening practices

Full mill lengths will be cut to lengths between 12 ft and 19 ft long. Packages longer than 44 inches may have additional freight charges.

| 1-29 | $5.42 |

| 30-74 | $2.32 |

| 75-104 | $2.03 |

| 105+ | $1.80 |

CPO-06875 has a 0.6875 in diameter with Standard Chrome. The base material is 1045 Carbon Steel with a yield strength of 75,000 psi.

ASTM A108 is the most commonly used and economical grade of shafting for hydraulic cylinder components, blower shafts, and mandrels.

- Extremely smooth surface finish

- Excellent wear and corrosion resistance

- Good strength and impact properties

- Good machinability

- Reasonable weldability

- Fair response to normal heat treating and induction hardening practices

Full mill lengths will be cut to lengths between 12 ft and 19 ft long. Packages longer than 44 inches may have additional freight charges.

| 1-29 | $4.00 |

| 30-59 | $2.00 |

| 60-119 | $1.50 |

| 120+ | $1.33 |

1.375 in clevis pin with two 0.173 in holes that can be used to retain the pin with cotter pins or locking pins. Cotter pins not included.

This U-cup style buffer ring offers an asymmetric sealing lip profile, chamfered sealing edges, and pressure relieving capabilities to prevent inner pressure entrapment when employed in a tandem sealing system. This rod buffer seal is designed to absorb impact pressure fluctuations under high-load conditions thus increasing the life of the primary seal.

Urethane Material | 3 in Nominal Inner Diameter | Buffer Seal