Search Results

Filter Your Search

Category Group

Category Group

Shop by Category

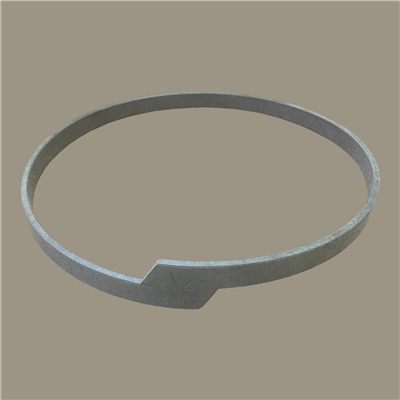

Solid Urethane backup ring with a flat cross-section.

95A Durometer | Urethane Material | 4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation

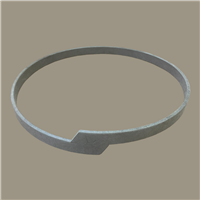

Style 580 Square O-rings are circular elastomeric rings that create a seal between two or more parts. They are made from a variety of materials, including BUNA-N rubber, and are used in a variety of industries, including automotive, aerospace, and manufacturing.

Buna-N Rubber Material | 2 1/2 in Nominal Inner Diameter | 3/16 in Cross Section | Square O-ring

Features

- Pressure range varies according to diametral clearance

- Temperature range of -40 °F to -240 °F

Style 580 Square O-rings are circular elastomeric rings that create a seal between two or more parts. They are made from a variety of materials, including BUNA-N rubber, and are used in a variety of industries, including automotive, aerospace, and manufacturing.

Buna-N Rubber Material | 3 in Nominal Inner Diameter | 3/16 in Cross Section | Square O-ring

Features

- Pressure range varies according to diametral clearance

- Temperature range of -40 °F to -240 °F

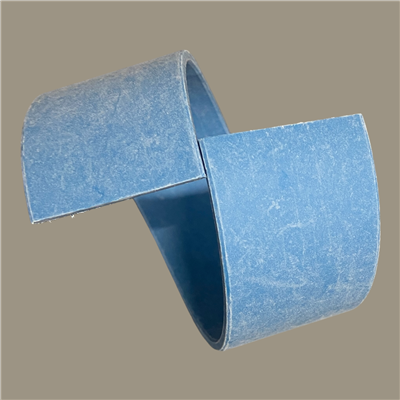

Wear rings provide a hard-wearing surface that protects the cylinder walls and the piston rod from scoring and abrasion. By maintaining alignment and reducing side loads, these rings facilitate smoother piston movement and lower friction levels.

Nylon Material | 3 in Nominal Inner Diameter | 1/8 in Cross Section | Wear Ring

Features

- Protection Against Wear

- Reduced Friction

- Extended Cylinder Life

- Operational Efficiency

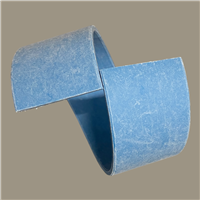

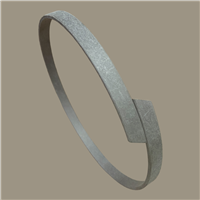

Wear rings provide a hard-wearing surface that protects the cylinder walls and the piston rod from scoring and abrasion. By maintaining alignment and reducing side loads, these rings facilitate smoother piston movement and lower friction levels.

Nylon Material | 3 1/4 in Nominal Inner Diameter | 1/8 in Cross Section | Wear Ring

Features

- Scarf Cut wear ring

- Protection Against Wear

- Reduced Friction

- Extended Cylinder Life

- Operational Efficiency

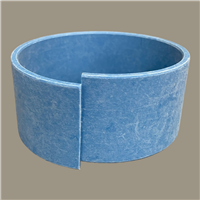

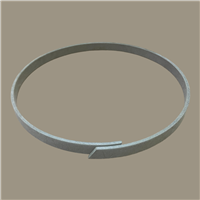

Wear rings provide a hard-wearing surface that protects the cylinder walls and the piston rod from scoring and abrasion. By maintaining alignment and reducing side loads, these rings facilitate smoother piston movement and lower friction levels.

Nylon Material | 5 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Wear Ring

Features

- Scarf Cut wear ring

- Protection Against Wear

- Reduced Friction

- Extended Cylinder Life

- Operational Efficiency

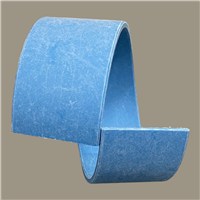

Wear rings provide a hard-wearing surface that protects the cylinder walls and the piston rod from scoring and abrasion. By maintaining alignment and reducing side loads, these rings facilitate smoother piston movement and lower friction levels.

Nylon Material | 7 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Wear Ring

Features

- Scarf Cut wear ring

- Protection Against Wear

- Reduced Friction

- Extended Cylinder Life

- Operational Efficiency

Suffix “SH” designates slotted heel design, “V” designates fluorocarbon material, and “B” designates carboxilated nitrile material.

90A Durometer | Urethane Material | 1 in Nominal Inner Diameter

Features

- Slotted heel design

- Slots in the heel allow excess hydraulic fluid to bypass the wiper