Search Results

Search Filters

-

Kraken Bearings x

Filter Your Search

Length

Length

Outside Diameter

Outside Diameter

Shaft Size / Inside Diameter

Shaft Size / Inside Diameter

Shop by Category

- Accessories(549)

- Braided Packing(124)

- Acrylic Graphite Packing ML402(8)

- Acrylic PTFE Packing ML2225(8)

- Aramid PTFE Packing ML4800(8)

- Carbon PTFE Packing ML4461(8)

- Flax PTFE Packing 219(8)

- Flexible Graphite Packing ML2001(10)

- GFO® Packing ML4002(8)

- High Performance Carbon Packing ML560(8)

- High Performance PTFE Packing ML2240(8)

- Pre-lubricated PTFE Packing ML2235(8)

- PTFE Packing ML2238(8)

- PTFE Graphite Packing ML3600(8)

- Tek-Pro Aramid PTFE Packing ML6225(8)

- Lantern Rings(8)

- Seating Tools(6)

- Packing Hooks(3)

- Packing Lube(1)

- Cylinder Components(768)

- Cylinder Repair Bench Products(19)

- Kraken Bearings(48)

- Round Bar(245)

- Seals(26,283)

- Seal Kits(17,589)

- Tube(328)

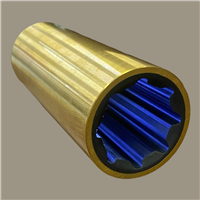

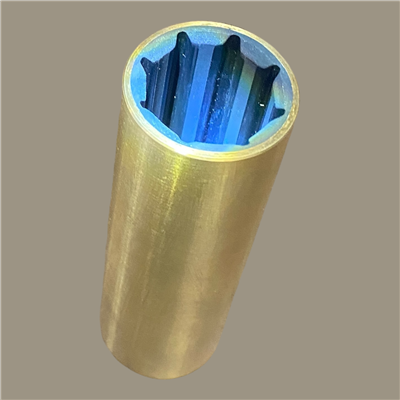

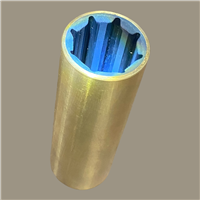

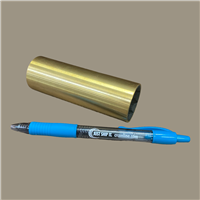

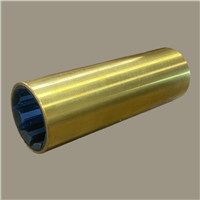

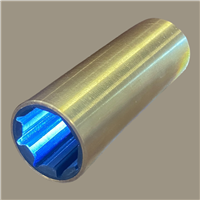

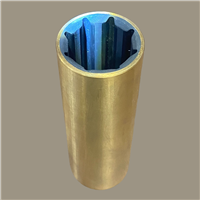

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life

Kraken marine bearings are rubber-lined brass bearings that are compatible with various shaft sizes and suitable for a wide range of marine vessels, from pleasure boats to commercial ships. They are designed for use as stern tube bearings, strut bearings, and rudder or pintle bearings.

Constructed with durable rubber and corrosion-resistant brass, Kraken bearings offer exceptional wear resistance, even in harsh marine environments. Kraken bearings reduce friction and absorb forces generated by shaft rotation, ensuring smooth operation, and extending the lifespan of the propulsion system.

The precision-engineered design ensures proper alignment and reduces vibration, resulting in quieter operation and minimized stress on the shaft. The grinding method used in the manufacturing process ensures a concentric bearing that meets or exceeds clearance and tolerance as per U.S. Navy Standard, BuShips plan number 810-1385664.

A cutlass bearing, also known as a stern tube or strut bearing, is a crucial component in marine propulsion systems. It supports and aligns the propeller shaft within the boat’s strut or stern tube. Regular maintenance is necessary to detect wear or damage and maintain optimal performance.

Kraken bearings can also be used in industrial applications such as pump bearings for power plants or wastewater treatment plants.

- Reduced vibration

- Quiet operation

- Concentric design

- Long service life