Cylinder Head Caps

Search in Category

Filter Your Search

Cylinder Bore

Cylinder Bore

Threads (A)

Threads (A)

Shop by Category

HC-2500-12 has a 3 in OD and is made to fit a 2 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-3000-12 has a 3.5 in OD and is made to fit a 2.5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-3500-12 has a 4 in OD and is made to fit a 3 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

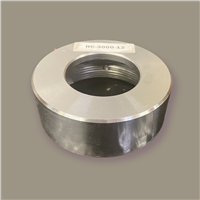

HC-4000-12 has a 4.5 in OD and is made to fit a 3.5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-4500-12 has a 5.25 in OD and is made to fit a 4 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-5000-12 has a 5.75 in OD and is made to fit a 4.5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-5500-12 has a 6.5 in OD and is made to fit a 5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-5625-12 has a 6.5 in OD and is made to fit a 5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-5625-8 has a 6.5 in OD and is made to fit a 5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

HC-6500-12 has a 7.5 in OD and is made to fit a 6 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.